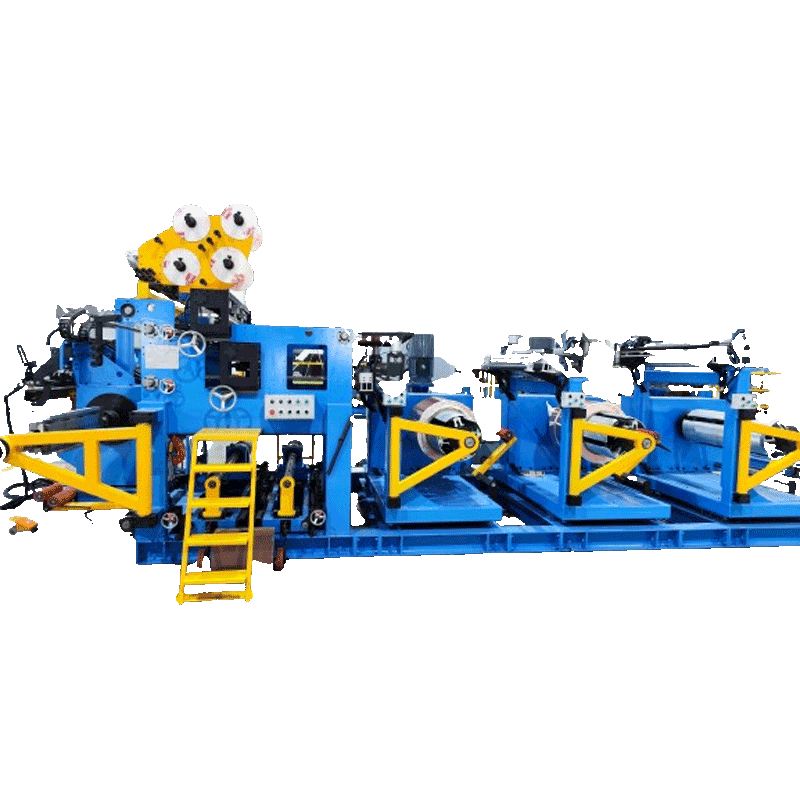

Gariiradda foornada ee LV waxay isticmaashaa dhumucyo kala duwan oo naxaas ah ama bireed aluminium ah sidii kaari ahaan, walax dahaar ballaadhan oo nooc ah sida dahaarka lakabka, dabaysha dhammaystiran ee mashiinka dabaylaha nooca bireed, samaynta gariiradda duuban.

Qalabkan waxa kale oo lagu dabaqi karaa dabaylaha gariiradda isku midka ah ee warshadaha korontada.

Mashiinku wuxuu qaataa habka xakamaynta PLC oo leh sifooyinka heerka sare ee otomatiga.

ⅡHalabuurka iyo Shaqada Qalabka

BR/III-1100 Mashiinka dabaysha ee saddex-lakabka ah waxaa ka mid ah

1) Aaladda dahaarka dahaarka 2) Qalab dabaysha 3) Qalabka dahaadhka lakabka

4) Qaybaha jir ee ugu muhiimsan 5) Qalabka alxanka 6) Qalabaynta iyo nadiifinta

7) Qalabka wax lagu gooyo 8) Qalabka dahaadhka dhamaadka ah ee aan gariiradda lahayn iwm

III. Halbeegyada Farsamo ee ugu muhiimsan

| Sr# | ITEM | QAABKA |

| 1 | Gariiradda | Baaxadda habaynta |

| 1.1 | Dhererka axial | 250-1100 mm |

| 1.2 | Dhererka axial (ku dar sunta rasaasta) | 400 ~ 1760 mm (oo leh sunta rasaasta RH 16 inch, LH 10inch) |

| 1.3 | Dhexroorka dibadda (Max) | Φ1000 |

| 1.4 | Qaab gariiradda | Miisaanka wareegsan/cylindrical/leydi/xagal / gariiradda ≤2000KG |

| 1.5 | Dhererka xarunta | 850mm |

| 2 | Qalabka gariiradda | bireed naxaas ah, bireed aluminium |

| 2.1 | Ballaca | 250-1100 mm |

| 2.2 | Dhumucda (Max) (Guud ahaan dhumucda) | Naxaasta birta ah: 0.3 ~ 2.5mm Foornada aluminium: 0.4 ~ 3mm |

| 2.3 | Dhexroorka gariiradda hoose | Φ400-500mm |

| 2.4 | Dhexroorka gariiradda (Max) | φ1000mm |

| Gawaarida ka saar | Saddex qaybood oo madaxbannaan |

| 3.1 | Dhererka dhululubada sidda | 1150 mm |

| 3.2 | Balaadhinta kala duwanaanshaha dhululubada | Φ380~φ520 |

| 3.3 | Kartida (Max) | 2000KG |

| 3.4 | Xoog balaadhinta (Koronto) | 0~15000N Xoog balaadhinta tallaabo la'aan la hagaajin karo |

| 3.5 | Habka sixitaanka | Buugga/Automaatigga ah |

| Mashiinka dabaysha |

|

| 4.1 | Xawaaraha dabaylaha | 0 ilaa 20 rpm |

| 4.2 | Wareegga shaqada (Max) | ≥ 8000N·M |

| 4.3 | Awood dabaysha | 20-30 KW |

| 4.4 | Habka xakamaynta xawaaraha | Isbeddelka soo noqnoqda ee nidaaminta xawaaraha stepless |

| 4.5 | Usha dabaylaysa | 50*90mm |

| 5 | Qalabka alxanka |

|

| 5.1 | Habka alxanka | TIG |

| 5.2 | Qabashada dhumucda alxanka bar | ≤20mm |

| 5.3 | Xawaaraha alxanka | Xawaaraha otomaatiga ah 0 ~ 1m/min Nidaaminta xawaaraha aan talabada lahayn |

| 6 | Qalabka goynta |

|

| 6.1 | Qaab goynta | Lead Screw Goynta saxanka |

| 6.2 | Xawaaraha jarista | 1.5 m / daq |

| 6.3 | Dhererka goynta | 1150mm |

| 7. | Lakabka dahaadhkagariirqalab | |

| 7.1 | Dahaarka lakabka ayaa lagu rakibay usheeda dhexe | 2 qaybood |

| 7.2 | Dhexroorka daboolka lakabka duuban | ≤φ400 mm |

| 7.3 | Dhexroorka duubka dahaadhka lakabka | φ76 mm |

| 7.4 | Balaadhka duudduuban dahaadhka lakabka | 250-1150 mm |

| 7.5 | Habka xiisadda usheeda dhexe ka saar | Nooca pneumatic |

| 8. | Thedhamaadqalabka dahaarka daaha |

|

| 8.1 | Tirada | Bidix iyo midig mid kasta 4 qaybood |

| 8.2 | Dahaarka dhamaadka ka baxsan dhexroorka | ≤φ350 mm |

| 8.3 | Dhexroorka dahaarka dhamaadka | Φ56 mm |

| 8.4 | Ballaca dahaarka dhamaadka | 10-100mm |

| 9. | Rqalabaynta (foil alignment) | Imadaxbannaan 3 qaybood |

| 9.1 | Habka hagaajinta | Nidaamka korontada |

| 9.2 | Dib u hagaajinta saxnaanta | Random±0.4 mm 20 gariiradda lakabka ±1mm |

| 10. | Nidaamka xakamaynta korantada | PLC habka xakamaynta tooska ah |

| 10.1 | Tirada dhijitaalka ah | 4-dijital (0-9999.9) Tirinta saxnaanta 0.1 leexashada |

| 10.2 | Interface Operation | Shaashada taabashada midabka |

| 11. | Mid kale |

|

| 11.1 | Qalabka goynta lakabka | Habaynta laba qaybood |

| 11.2 | Qalab xariif ah oo darafyada wax laga saarayo | Habaynta saddex qaybood |

| 11.3 | Qalab nadiifinta walxaha qashinka ah | Habaynta saddex qaybood |

| 11.4 | Haanta biyaha qaboojinta alxanka | habaynta |

| 11.5 | Bixinta Korontada | 3-PH,380V/50HZ (waa la beddeli karaa) |

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com